RESUMO

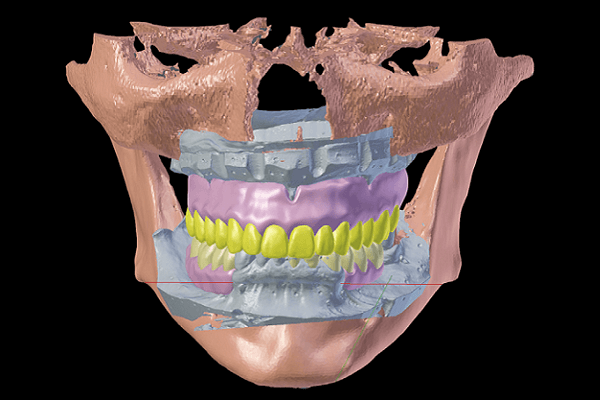

O objetivo deste trabalho foi descrever a técnica de DDI (desenho digital integral) em substituição ao ED (enceramento diagnóstico), mudando um paradigma na Odontologia. Com o uso do DDI, não é necessário realizar o enceramento diagnóstico para estabelecer a meta protética. Esta é obtida digitalmente em um ambiente 3D, com mais requinte de informações e maior precisão. O DDI é então materializado (prototipado) utilizando uma impressora 3D, dentro do ambiente do consultório. Atualmente, os recursos CAD/CAM de baixo custo estão disponíveis para uso odontológico, e os resultados obtidos com esta tecnologia justificam a incorporação do tratamento 3D. Desta forma, a técnica do enceramento dental estaria próxima do fim, sendo que, em um futuro próximo, dentistas/técnicos de prótese serão dental digital designers e todo o conhecimento se voltará para o domínio dos programas de informática, e não para aquisição de equipamentos complexos e de alto custo.

Palavras-chave – Projeto auxiliado por computador; Projeto usinado pelo computador; Tomografia computadorizada de feixe cônico; Impressão tridimensional.

ABSTRACT

The objective of this study was to describe the IDD technique (integrated digital design) to replace the DW (diagnostic waxing) as a paradigm shift in Dentistry. In this way, it is not necessary to perform the diagnostic waxing to establish the prosthetic outcomes. This is achieved in a 3D environment, with more information refinement and greater accuracy. The IDD is then materialized (prototyped) using a 3D printer within the dental office. Currently, the CAD/CAM resources are low-cost and available for dental use, with the obtained results justifying the incorporation of the 3D dental treatment. Thus, the diagnostic waxing would be close to an end; in the near future, clinicians/laboratory technicians will be dental digital designers and all knowledge will be managed to computer software domain and not to the acquisition of complex and expensive production equipment.

Key words – Computer-aided design; Computer-aided machining; Cone beam computerized tomography; 3D printing.

Referências

- Mörmann W. The origin of the Cerec method: a personal review of the first 5 years. Int J Comput Dent 2004;7(1):11-24.

- Mormann W. The evolution of the Cerec system. J Am Dent Assoc 2006 137(Suppl):7s-13s.

- Rekow ED. Dental CAD/CAM systems a 20-years success story. J Am Dent Assoc 2006;137(Suppl.):5s-6s.

- Verde MA, Morgano SM. A dual-purpose stent for the implant-supported prosthesis. J Prosthet Dent 1993;69(3):276-80.

- Engelman MJ, Sorensen JA, Moy P. Optimum placement of osseointegrated implants. J Prosthet Dent 1988;59:467-73.

- Jacobs R, Adriansens A, Verstreken K, Suetens P, van Steenberghe D. Predictability of a three-dimensional planning system for oral implant surgery. Dentomaxillofac Radiol 1999;28(2):105-11.

- Sarment DP, Al-Shammari K, Kazor CE. Stereolithographic surgical templates for placement of dental implants in complex cases. Int J Periodontics Restorative Dent 2003;23(3):287-95.

- Dreiseidler T, Neugebauer J, Ritter L, Lingohr T, Rothamel D, Mischkowski RA et al. Accuracy of a newly developed integrated system for dental implant planning. Clin Oral Implants Res 2009;20(11):1191-9.

- Rosenfeld AL, Mandelaris GA, Tardieu PB. Prosthetically directed implant placement using computer software to ensure precise placement and predictable prosthetic outcomes. Part 1: diagnostics, imaging, and collaborative accountability. Int J Periodontics Restorative Dent 2006;26(3):215-21.

- Rosenfeld AL, Mandelaris GA, Tardieu PB. Prosthetically directed implant placement using computer software to ensure precise placement and predictable prosthetic outcomes. Part 2: rapid-prototype medical modeling and stereolithographic drilling guides requiring bone exposure. Int J Periodontics Restorative Dent 2006;26(4):347-53.

- Rosenfeld AL, Mandelaris GA, Tardieu PB. Prosthetically directed implant placement using computer software to ensure precise placement and predictable prosthetic outcomes. Part 3: stereolithographic drilling guides that do not require bone exposure and the immediate delivery of teeth. Int J Periodontics Restorative Dent 2006;26(5):493-9.

- Otto T, Schneider D. Long-term clinical results of chairside Cerec CAD/CAM inlays and onlays: a case series. Int J Prosthodont 2008;21(1):53-9.

- Trost L, Stines S, Burt L. Making informed decisions about incorporating a CAD/CAM system into dental practice. J Am Dent Assoc 2006;137(Suppl.):32s-6s.

- Gürel G. Applying foundational principles to digital technologies. Ensuring success in aesthetic dentistry. Dent Today 2014;33(5):144-8.

- Fotopoulos F. Reverse engineering in computer applications. E-book 2015. Disponível em: https://www.megasecurity.org/papers/ReverseEnginering.pdf .

- Keshvad A, Hooshmand T, Asefzadeh F, Khalilinejad F, Alihemmati M, Van Noort R. Marginal gap, internal fit, and fracture load of leucite-reinforced ceramic inlays fabricated by CEREC inlab and hot-pressed techniques. J Prosthodont 2011;20(7):535-40.

- Baroudi K, Ibraheem SN. Assessment of chair-side computer-aided design and computer-aided manufacturing restorations: a review of the literature. J Int Oral Health 2015;7(4):96-104.

- Fasbinder D. The Cerec system: 25 years of Chairside CAD/CAM Dentistry 2010 141(Suppl.2): 3S-4S.

- Guichet D. Digitally enhanced dentistry: the power of digital design. J Calif Dent Assoc 2015;43(3):135-41.

- https://www.3dsystems.com/es/projet1200/dental.

- https://www.formlabs.com/products/form-1-plus/.

- Kopp S, Kühmstedt P, Notni G, Geller R. G-scan – mobile multiview 3-D measuring system for the analysis of the face. Int J Comput Dent 2003;6(4):321-31.

- Creaform lab. An introduction to 3D scanning. Ebook series [On-line]. Disponível em https://www.creaform.com/educ. Acesso em: 19-10-2015.