RESUMO

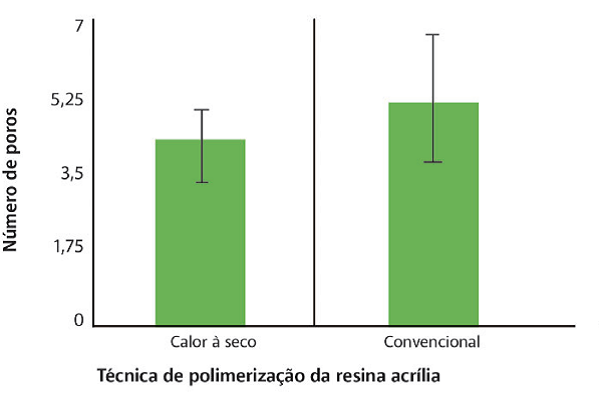

Objetivo: avaliar a rugosidade, microdureza Knoop e porosidade de uma resina acrílica termopolimerizável convencional polimerizada por um equipamento experimental. Material e métodos: dois grupos de corpos-de- -provas foram confeccionados (n=14), totalizando 28 espécimes, a partir de três matrizes de 30 mm de diâmetro por 3 mm de espessura em aço inoxidável, que foram incluídas em mufl a metálica. A resina acrílica convencional (Artigos Odontológicos Clássico) foi manipulada conforme orientação do fabricante – três partes de polímero para uma parte de monômero – e inserida na mufl a, mantida na prensa hidráulica sob 1,25 t por 12 horas. Os corpos-de-prova do grupo-controle (C) passaram por polimerização em polimerizadora (Protécni Equipamentos) sob a temperatura de 74ºC durante oito horas, seguido por uma temperatura de 100ºC durante uma hora. Os corpos-de-prova do grupo-teste (T) foram submetidos ao ciclo na polimerizadora experimental (Speed, Fenix Indústria e Comércio) durante 20 minutos, com as resistências do equipamento permanecendo em 130ºC durante todo o ciclo. Após remoção dos corpos-de-prova das mufl as, foram executados acabamento e polimento na politriz (Aropol 2V, Arotec) em ambos os lados com lixas de granulações 320, 400, 600, 1.200 e 2.000 (Saint-Gobain do Brasil Prod.Ind.), e submetidos ao testes de microdureza Knoop (HVS 1000, PanTec), rugosidade (SurfTest SJ-210, Mitutoyo) e porosidade. Os dados foram submetidos ao teste t de Student para amostras independentes, adotando-se o nível de signifi cância de 5%. Resultados: não houve diferença estatisticamente signifi cativa na rugosidade de superfície (p=0,725) e na microdureza Knoop (p=0,204) entre os grupos, porém, em relação à porosidade, constatou-se um número de poros signifi cativamente menor no grupo-teste (p=0,013). Conclusão: o experimento produziu uma resina acrílica com menos porosidade, entretanto com semelhante microdureza e rugosidade.

Palavras-chave – Resinas acrílicas; Polimerização; Bases de dentadura.

ABSTRACT

Objective: to evaluate roughness, Knoop microhardness and porosity of a conventional thermopolymerizable acrylic resin polymerized by experimental equipment. Material and methods: two groups of specimens were prepared (n=14), totaling 28 specimens from three stainless steel matrices measuring 30 mm in diameter and 3 mm thick, which were included in a metal fl ask. The conventional acrylic resin (Artigos Odontológicas Clássico) was manipulated according to the manufacturer’s instructions, 3 parts of polymer to 1 part of monomer, and inserted into the fl ask and kept in the hydraulic press under 1.25 t for 12 hours. The specimens from the control group (C) was polymerized in an electric polymerizer by water bath technique (Protécni Equipamentos) at a temperature of 74ºC for 8 hours, followed by a temperature of 100ºC for 1 hour. The specimens from the test group (T) were cycled in an experimental polymerizer (Speed, Fenix Indústria e Comércio) for 20 minutes, with the equipment resistance remaining at 130ºC throughout the cycle. After removing the fl ask, fi nishing and polishing were carried out using a polishing machine (Aropol 2V, Arotec) on both sides with 320, 400, 600, 1.200 and 2.000 grit sandpaper (Saint-Gobain do Brasil Prod. Ind.) and submitted to Knoop microhardness tests (HVS 1000, PanTec), roughness (SurfTest SJ-210, Mitutoyo) and porosity. The data were subjected to Student’s t test for independent samples, adopting a signifi cance level of 5%. Results: there was no statistically signifi cant diff erence in surface roughness (p=0.725) and Knoop microhardness (p=0.204) between the groups, however, porosity, a signifi cantly lower number of pores was found in the test group (p=0.013). Conclusion: the experimental equipment produced an acrylic resin with less porosity, however with similar microhardness and roughness.

Key words – Acrylic resins; Polymerization; Denture bases.

Referências

- Ismiyati T, Alhasyimi AA. Effect of chitosan and acrylic acid addition to acrylic resin on porosity and streptococcus mutans growth in denture base. Eur J Dent 2023;17(3):693-8.

- Khan AA, Fareed MA, Alshehri AH, Aldegheishem A, Alharthi R, Saadaldin SA et al. Mechanical properties of the modified denture base materials and polymerization methods: a systematic review. Int J Mol Sci 2022;23(10):5737.

- Gad MM, Fouda SM, ArRejaie AS, Al-Thobity AM. Comparative effect of different polymerization techniques on the flexural and surface properties of acrylic denture bases. J Prosthodont 2019;28(4):458-65.

- Costa RTF, Pellizzer EP, Vasconcelos BCDE, Gomes JML, Lemos CAA, de Moraes SLD. Surface roughness of acrylic resins used for denture base after chemical disinfection: a systematic review and meta-analysis. Gerodontology 2021;38(3):242-51.

- Silva RVDR, Costa MI, Jarros IC, Del Bel Cury AA, Sidhu SK, Negri M et al. Effect of silicon dioxide coating of acrylic resin surfaces on candida albicans adhesion. Braz Oral Res 2020;34:e110.

- Al-Thobity AM. The impact of polymerization technique and glass-fiber reinforcement on the flexural properties of denture base resin material. Eur J Dent 2020;14(1):92-9.

- Ari MDA, Rahmania PN, Kusumaningsih T, Nugraha AP, Ramadhani NF, Fahreza RR et al. Denture stomatitis- tis in diabetic senile patient: pathophysiology and management review. Biochem Cell Arch 2021;21(02):3223-8.

- Onwubu SC, Mdluli PS. Comparative analysis of abrasive materials and polishing system on the surface roughness of heat-polymerized acrylic resins. Eur J Dent 2022;16(3):573-9.

- Chander NG, Venkatraman J. Mechanical properties and surface roughness of chitosan reinforced heat polymerized denture base resin. J Prosthodont Res 2022;66(1):101-8.

- Moslehifard E, Ghaffari T, Zarei K, Karimoghli M. Evaluation of microhardness in two types of denture bases after using sodium hypochlorite and NatureDent disinfecting agents. J Dent Res Dent Clin Dent Prospects 2022;16(3):196-203.

- Aguirre BC, Chen JH, Kontogiorgos ED, Murchison DF, Nagy WW. Flexural strength of denture base acrylic resins processed by conventional and CAD-CAM methods. J Prosthet Dent 2020;123(4):641-6.

- Song SY, Kim KS, Lee JY, Shin SW. Physical properties and color stability of injection-molded thermoplastic denture base resins. J Adv Prosthodont 2019;11(1):32-40.

- Moslehifard E, Ghaffari T, Abolghasemi H, Dizaj SM. Comparison of conventional pressure-packed and injection molding processing methods for an acrylic resin denture based on microhardness, surface roughness, and water sorption. Int J Dent 2022:2022:7069507.

- Kaur L, Aras MA, Chitre V, Nagarsekar A, Ferreira AN. Evaluation and comparison of flexural strength, surface roughness and porosity percentage of denture base resins incorporated with Thymoquinone and silver nano-antimicrobial agents-an in vitro study. J Oral Biol Craniofac Res 2022;12(5):716-20.

- Bachtiar BM, Fath T, Widowati R, Bachtiar EW. Quantification and pathogenicity of candida albicans in denture-wearing and non- denture-wearing elderly. Eur J Dent 2020;14(03):423-8.

- Ismiyati T, Alhasyimi AA. Effect of chitosan and acrylic acid addition to acrylic resin on porosity and streptococcus mutans growth in denture base. Eur J Dent 2023;17(3):693-8.

- Palaskar JN, Singh S, Mittal S. Evaluation and comparison of different polymerization techniques, curing cycles, and thicknesses of two denture base materials. Indian J Dent Res 2019;30(4):583-9.

- Yılmaz Atalı P, Doğu Kaya B, Manav Özen A, Tarçın B, Şenol AA, Tüter Bayraktar E et al. Assessment of micro-hardness, degree of conversion, and flexural strength for single-shade universal resin composites. Polymers (Basel) 2022;14(22):4987.

- Pirmoradian M, Hooshmand T, Jafari-Semnani S, Fadavi F. Degree of conversion and microhardness of bulk-fill dental composites polymerized by LED and QTH light curing units. J Oral Biosci 2020;62(1):107-13.

- Schoeffel AC, Bagio P, Sakima VT, Soares S, Neppelenbroek KH, Urban VM. Knoop microhardness of conventional and microwaved denture base acrylic resins. Indian J Dent Res 2019;30(6):927-32.